News

1. Structural differences

Gate valves have a more complex structure than globe valves. Firstly, gate valves are classified into rising stem gate valves and hidden stem gate valves based on their different structures, while globe valves do not. Secondly, in terms of appearance and structure, gate valves are shorter in length than globe valves, but higher in height. So, gate valves require more installation space, especially rising stem gate valves.

2. Differences in Principle

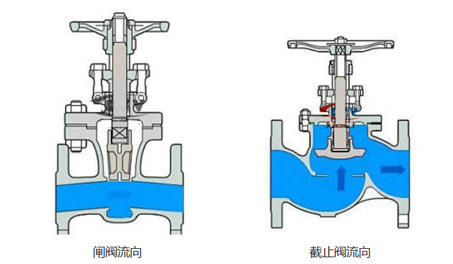

The operation methods of gate valves and globe valves are similar, both of which rotate the handwheel and the valve stem drives the valve plate to move up and down to achieve flow control. The difference between the two is that gate valves can only be fully opened and fully closed. When the gate is opened or closed, the stroke is greater and the opening and closing time is longer. The distance between the shut-off valve plate and the sealing surface is short, the movement stroke of the valve plate is small, and the valve plate of the shut-off valve can stop at a certain position during movement for flow regulation. This is something that gate valves do not have. In addition, when installing gate valves in pipelines, there is no requirement for inlet and outlet directions, and the medium can flow in both directions. The globe valve has import and export directions, and China's "Three Modernizations of Valves" has provided flow direction regulations for globe valves, which are all from top to bottom.

3. Difference in Flow Resistance

Because gate valves can only be fully opened and fully closed, when they are in the fully open state, the flow channel in the entire pipeline is straight through, and the fluid medium flows through the valve body channel without any obstruction, with almost zero flow resistance. And for globe valves, when the medium flows through the valve body channel, the flow direction is from top to bottom, and it is subject to greater resistance from the valve plate.

4. Differences in maintenance and repair

During maintenance and repair of gate valves, it is necessary to remove them from the pipeline, which incurs high labor costs. In most cases, the valve seat and disc of a globe valve can be directly replaced online without disassembling the entire valve. Therefore, when used as a shut-off valve, globe valves are suitable for welding valves and pipelines together.

Recruitment of National Agents:+86-151 6780 1146

Recruitment of National Agents:+86-151 6780 1146